Torsion Axles

FIND OUT MORE...

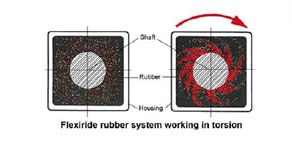

The Flexiride

rubber torsion axle consists of three primary components: a rubber cartridge, support bushing and spindle arm.

The cartridge is comprised of strong proprietary formula rubber bonded to a steel shaft. The bonding process

used results in a bond strength exceeding the strength capabilities of the associated steel parts. Unlike the solutions used by competition, the system operates in shear rather

than compression providing more angular compliance, a better damping effect and a smoother ride. The nylon

support bushing maintains camber and contributes additional damping control. The spindle arm is a one piece forging with a splined joint connecting it to

the cartridge. The splines, at six degree intervals, make an exceptionally strong connection while providing

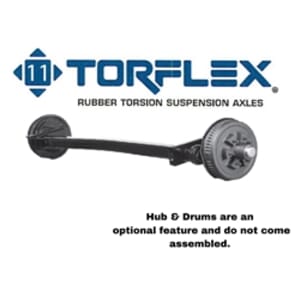

a range of starting angles. Components are available in

four sizes: 2000, 3500, 5200, and 7000 lbs axle capacities.

Flexiride®

Advantages versus Leaf Spring Axles:

Durability: The cartridge construction

offers superior resistance to abrasive road

elements, increasing the life and durability of the axle. Because the cartridge is press fit inside the

axle tube, it forms a water ltight seal, thus allowing the axle immersion without having the tube inside

exposed to corrosion.

Smoother

ride and longer life: The high quality

proprietary formula rubber guarantees a smoother ride and longer life. The independent suspension allows

each wheel to travel totally independent from the others. A smoother ride, less sway and reduced noise is

achieved with the rubber suspension.

Progressive

Torque: It

increases carrying capacity as the lad is applied, allowing smooth ride even with an unloaded trailer.

Safer

and stronger: The specially engineered

one piece forged spindle

arm creates a system which is safer and stronger than any welded unit. The axle tube acts like an extra cross

member, adding strength and preventing frame twisting. The rubber cartridge is completely encapsulated

inside the axle tube, so there are no pinch points.

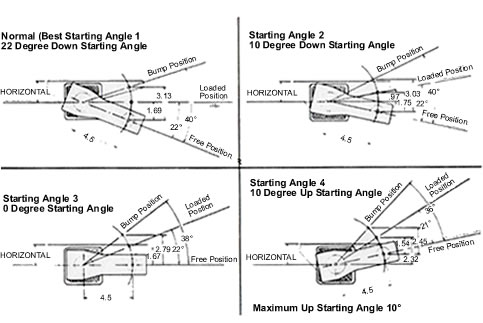

Adjustable:

The splined arm is adjustable for a range of starting angles to suit

special applications. The axle can

be built with various start angels to achieve desired trailer height.

Damping Control: Because of the rubber natural vibrations

absorbing capabilities, no shock absorbers are required.

Easy

replacement:

Unlike welded systems the Flexiride® spindle arm

can be removed easily for repair or replacement.

Quick

installation: The axle assembly requires

only four bolts to

mount reducing installation time.

Maintenance Free: Because there is no metal-to-metal contact,

there it eliminates the need for lubrication of the components. There are no suspension parts to wear out.

(spring shackles, hangers, etc.)

Built-to-suit axle system reduces lead

times and inventory.

Warranty: UCF offers a five year warranty on components,

that demonstrates how confident they are with the Flexiride® suspension.

The normal 22 degree starting angle maximizes the Flexiride® performance advantage, however, other starting angles are possible for special applications. This build-to-suit system eliminates the need for large inventories of different axle configurations and reduces lead times considerably.